Coat Hanger

Background

In my spare time, I like to make things for people with big ideas. Sometimes, however, the ideas are fairly small. How complex could something like a folding coat hanger be? Well, the answer is extremely. This project was a deep dive in to the world of plastics, working with prototypes in China, and in the US. As well, this project was a wonderful showcase of my skills as an engineer.

The Challenge:

To create a coat hanger that can fold vertically, and drop in to a suitcase. There must be a mechanism such as a button that allows to pop open the coat hanger. The coat hanger must lock in place when not in use in a closed position, and must also lock in an open position.

My Role:

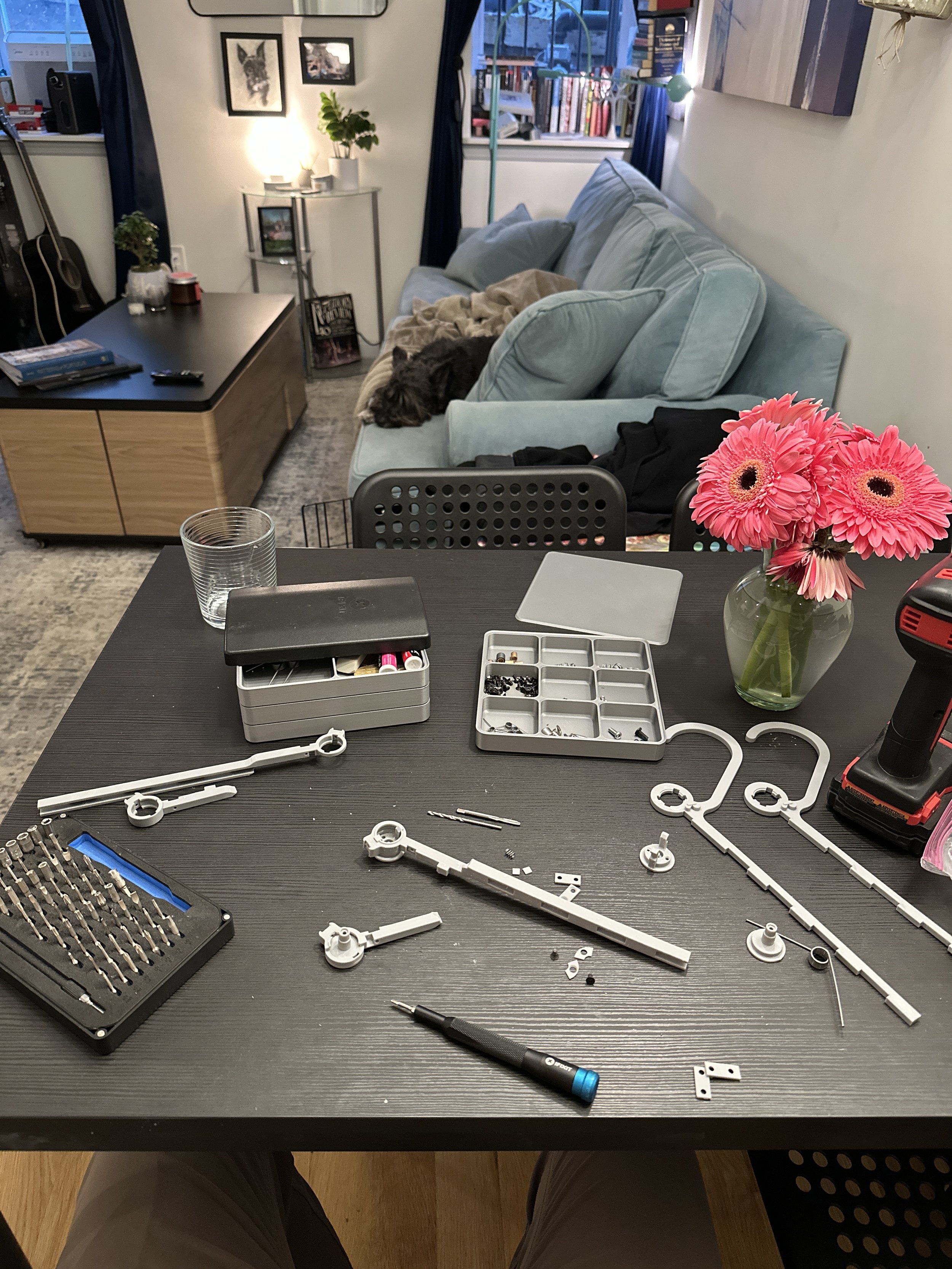

I did all of the engineering, testing, validation, 3D-Printing in my spare time. All files designed in Solidworks.

Process

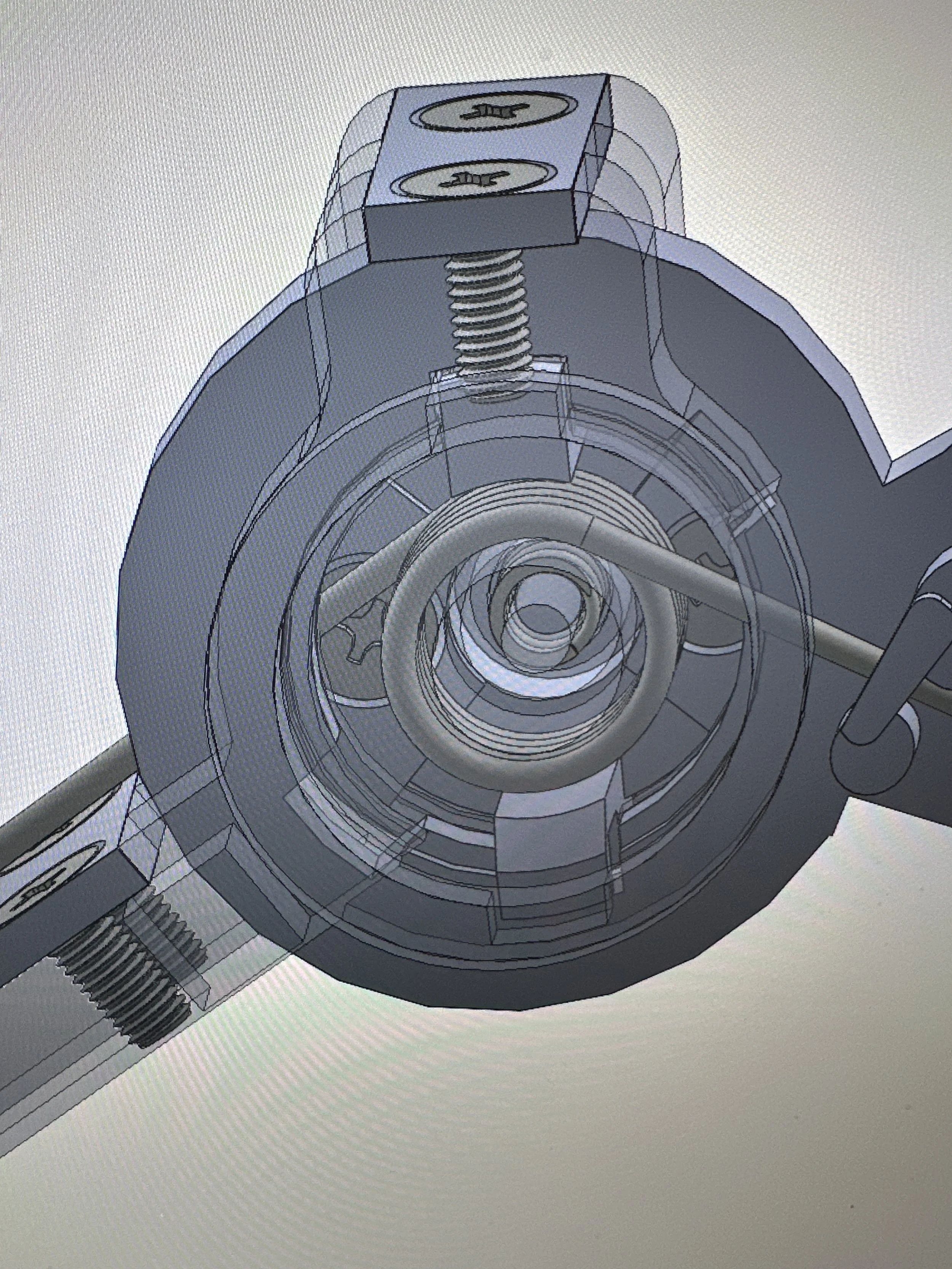

I was introduced to this project by a client on Fiverr. The client wanted a coat hanger that was automatically closing. Initially, I thought it would be a super simple project. This project ended up spanning 8 or 9 months. I went from a very simple hanging prototype, to making a fully working version. I spent many print hours on my Bambu X1-C to get the prints to come out right. The tolerances were also exceptionally difficult to get right. The hardware was fairly straight-forward. The inside of the coat hanger uses a very clever mechanism which when pushed in allows for the rotation of the hanging side of the coat hanger. The center of the mechanism has a spring which is compressed upon rotation. The wings on the back keep the button from popping out. It is not a straight-forward assembly process, but the design is SUPER cool, and extremely fluid to use. I was actually shocked at how much weight the hanger can hold as well. You can put any type of coat on it. I even have a 6 pound leather jacket which rests comfortably on the hanger without any sort of bending, warping, or breaking. With the current conditions of the product being 3D printed, the hanger lasts about 100 cycles before failure. The main failure point are the “key locks” that keep the hanger from rotating when not in use. I didn’t really do any simulations, as I can’t afford the solidworks software to do so. All of the design was done in solidworks.

Final Outcomes

Even though I warned my client about tooling costs upfront, ultimately they bailed due to the tooling cost.